As the pharmaceutical market continues to develop new and different formulas, delivery methods also evolve . According to data, over 25% of drugs that are currently in the development stage contain highly potent Active Pharmaceutical Ingredients (APIs). The main challenge? Developing these formulations into effective low-dose medicines. A potential answer? Liquid filled capsules, since they offer a more accurately dosed and homogeneous formulation.

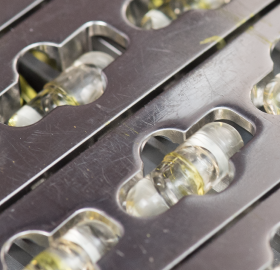

In fact, liquid filled capsules are one of the most common methods of drug delivery. They are composed of two hard capsule pieces that are specially designed for use with liquids and semi-solids. Liquid filled capsules are known for their improved stability, dosage form flexibility and need for fewer required stability studies.

Unlike softgels, which are known for their use in oil-based formulations, liquid filled capsules are more adaptable to different types of fillings, thereby meeting a wider range of product requirements. Plus, softgels contain glycerin and sorbitol, components that may affect the consumer. Meanwhile, liquid filled capsules are starch-free, gluten-free, and free of additives and preservatives.

Additional benefits associated with liquid filled capsules

Other reasons for liquid filled capsules’ popularity include:

- This dosage form can generate high potency oral products in less time, reducing your formula’s time to market.

- Liquid filling can provide homogeneity for low dose products, through the generation of a solution, even if your formula has a limitation.

- Liquid filling makes the capsule filling process safer for highly-potent APIs because the integration of API powders into the liquid excipient eliminates the risk of exposure for the machine operators.

Benefits for your formula

- Improved absorption, bioavailability, and stability

- Sustained release of the components

- Ease of coating

- Less gas transmission

- Dosage form flexibility

- Wide regulatory acceptance

- No transition from clinical to market capsules

To keep in mind

As you are evaluating this option, it is important to understand some characteristics of liquid filled capsules. First, like traditional hard capsules, liquid filled capsules are made of gelatin obtained from bovine bone, hide, and skin collagen. Vegetarian options, such as capsules made from hydroxypropyl methylcellulose (HPMC), are also available.

Second, liquid filled formulations require excipients such as lipophilic liquid or semisolid vehicles, solubilizing agents, surfactants, and emulsifying agents. Thus, there are a few considerations to keep in mind:

- The fill material must be chemically inert.

- You must verify that the fill material is compatible with the gelatin capsule you are going to use.

- Liquid filled capsules should not have more than 2% of moisture exchange with the shell.

Choose the right method for band sealing

Liquid filled capsules can be sealed by two different methods: hydro-alcoholic fusion (used for sealing the capsule and avoiding tampering) and banding. The last method involves the cap-body interface, which means banding the capsule with a layer of gelatin.

Be sure to test the quality of your capsules

The most common tests that you should run on your capsules are:

- Content uniformity

- Drug content

- Leak test

- Seal integrity

- Weight variation

- Disintegration

- Stability

According to Pharma Trends, you should be able to use stability testing to test the capsule’s physical characteristics, drug content and drug release after the capsule has been stored in stressed conditions.

Keep learning about capsule technology trends...

- Gelatin capsules vs. HPMC capsules: What are the differences?

- 5 Ways to Use G-CAPS® to Differentiate Your Product

- Flavored capsules: the next customization level

Why choose liquid formulation LQ-CAPS ®?

CapsCanada’s LQ-CAPS are made specifically to encapsulate liquid formulations. They:

- Are equally flexible and secure.

- Address a myriad of liquid-fill formulation issues.

- Provide a wide range of solutions, from bioavailability challenges to ease of scale-up.

- Provide faster and more consistent dissolution for optimized absorption.

- Are a versatile option for manufacturers wishing to formulate smaller products with fewer excipients.

Do you want to know more about liquid hard capsules? Get in touch with an encapsulation expert today.

.jpg)