This past March, the FDA approved the first liquid-filled aspirin capsule. PLx introduced a third aspirin option available to patients. The full-strength and low-dose version of Vazalore consist of hard capsules containing aspirin in liquid form. This product is based on the PLxGuard drug delivery platform aimed at delivering drugs to targeted areas of the gastrointestinal tract.

This new way of aspirin delivery could bring more options for OTC formulations because it opens the possibilities of re-introducing pre-existent products in different dosage forms, satisfying the market and consumer needs.

The differences between enteric-coated and liquid-filled aspirin

According to Harvard Health Publishing, the new formulation is made to release aspirin in the duodenum, which is the first part of the gut. This may help prevent stomach erosions and ulcers, which can occur when taking regular aspirin (also known as plain or immediate-release aspirin).

Aspirin is an NSAID that can be used to relieve pain, fever, and inflammation. Some people use it to prevent blood clots from causing cardiac issues like heart attacks and strokes.

Immediate release aspirin is a fast-acting pain reliever that is absorbed in the stomach. However, it is likely to increase stomach-related side effects. Although antacids are present in buffered aspirin, it is also absorbed in the stomach. Un-pleasers are believed to help reduce the amount of acid in the stomach and hence limit these negative effects. Buffering aspirin, on the other hand, has been demonstrated in tests to not affect this risk.

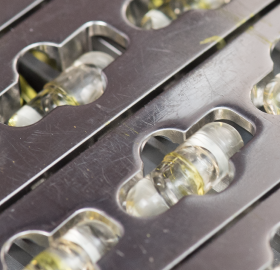

Valazore, the liquid-filled capsule version, like enteric-coated aspirin, is absorbed in the small intestine after passing through the stomach. It's different, though, because it is an IR aspirin. The capsule has been constructed to not disintegrate in the stomach's acidic environment. Instead, when it enters the small intestine, it dissolves and releases the aspirin. Vazalore was established to work swiftly while still protecting the stomach.

This recent drug release opens a discussion surrounding the benefits of liquid-filled capsules in different developments and formulations in the pharmaceutical industry and OTC markets.

Why Liquid Filled Capsules Could Be Better for Some Patients

A liquid-filled capsule can be broken down and absorbed into the bloodstream in as little as a few minutes, even though a tablet pill can take 20-30 minutes to absorb. As a result, liquid-filled capsules are often thought to be more powerful and faster-acting than tablet pills.

The contents may also be absorbed in a higher rate than tablet pills. Liquid-filled capsules, on the other hand, may wear off more quickly. Liquid and coated capsules are simpler to swallow than uncoated tablet pills, and they may leave less of an aftertaste or an unpleasant taste in the mouth.

Liquid-Filled Capsules: This delivery form has more advantages

Liquid-filled capsules can be a viable option for companies wishing to produce high-potency oral medicines with a reasonably simple commercial scale-up method. As a result, the method is used as quick product development and screening tool for promising chemicals that have low solubility, unique handling requirements, or other formulation problems.

The liquid-fill technique can also provide safer and more efficient handling because the powder API is incorporated into the liquid excipients, removing the risk of powder handling being exposed to further manipulation and processing. Through most of the manufacturing process, this strategy ensures that operators are not exposed to airborne powder. Liquids can also be easily piped between operations, ensuring that they are handled efficiently.

Keep learning about capsule technology trends...

- Are Liquid Filled Capsules the Right Delivery Method for Your Formula?

- Vitamin and Supplements Trends

- Clinical Trial Capsules: 4 Key Features to Look For

CapsCanada® offers gelatin and Hypromellose (HPMC) vegetarian/vegan capsules. LQ-CAPS® gelatin capsules are specially engineered for liquid fills and are an ideal choice for the dietary supplement market, pharmaceutical markets, and hygroscopic fills.

Our LFHC facility is well suited to support both process and product research as well as full-scale production. We also have pharmaceutical and dietary supplement development and production operations in South America. CapsCanada's three decades of hard capsule knowledge, along with these well-equipped locations, ensure optimal efficiency, production, and reliability.