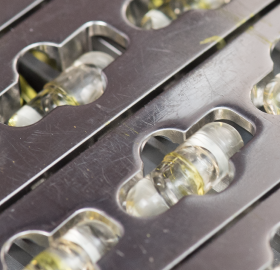

There are many reasons why a product development team might choose to formulate a drug or supplement for liquid delivery. For example, liquids can reduce development time, improve bioavailability, speed absorption and more. Once the decision to use liquid delivery is made, another equally important decision must also be made: What dosage form should be used—softgels or liquid-filled hard capsules (LFHC)?

For some time the “conventional” choice has been softgels. The primary advantages of softgels are that they are formed, filled and hermetically sealed in one operation; deter tampering; are easy to swallow; and are available in a variety of shapes, sizes and colors.

That said, there are many reasons why two-piece hard capsules should be considered an option for liquid filling and may often a better option.

LFHCs make product development easier

Easier product development, of course, increases cost-efficiency. Liquid-filled hard capsules…

- Are a pre-made dosage form – Unlike softgels, with 2-piece hard capsules there is no need to formulate the shell itself. Because of this, liquid filling in hard capsules can be done in-house with readily-available equipment.

- Enable small-scale filling – Small quantities of 2-piece hard capsules can be filled in-house with lab-scale equipment and just a few grams of formulation. In contrast, the pilot-size equipment that is available for making softgels is more expensive and requires more fill material.

LFHCs offer numerous manufacturing advantages

These advantages also increase cost-efficiency. With liquid-filled hard capsules, brands enjoy…

- Less infrastructure – One of the biggests advantages of LFHCs is that manufacturing does not require the significant investment in expensive gelatin preparation equipment, with its corresponding large facility footprint, that softgels require. LFHC manufacturing also eliminates the need to hold raw materials for this gelatin preparation. With LFHCs the capsules come pre-manufactured and ready to fill using readily-available and easy-to-use filling equipment. In contrast, softgels’ capital equipment requirements result in the need to use a specialized third-party manufacturer and work the associated costs and timeline issues into your plans.

- Faster manufacturing – While softgels take three to four days from gelatin prep to blister packing, all steps in the LFHC process cycle are completed in one day, including capsule banding or sealing.

- Less complex manufacturing – Softgel manufacturing is only done by a limited number of facilities; LFHC manufacturing is often done in-house. Equipment to produce LFHCs is less expensive and takes considerably less space than softgel manufacturing equipment; uses less than one-third the amount of electricity; requires less expertise to operate; and can be run with fewer people. LFHC’s simpler process also makes this dosage form more easily scalable.

- Less stringent manufacturing conditions – For softgels manufacturing, relative humidity at room temperature must be kept between 20 and 30%. Compare this to hard capsule filling, which can take place at up to 60% relative humidity at room temperature.

- No wastage of gelatin material – Softgel manufacturing results in gelatin wastage equal to up to 40% of the web size. No gelatin is wasted with gelatin-based hard capsules. Given today’s worldwide gelatin shortage, this is an important consideration.

- Option to fill in a nitrogen environment – As with softgels, when manufacturing LFHCs an inert gas such as nitrogen can be used to add an extra layer of protection for the fill material.

LFHCs are suitable for a much broader range of fill materials and drugs

Softgels are primarily used for oils and materials that are dissolved or suspended in carrier oils. Liquid-filled hard capsules offer those in the nutraceutical or pharma industry far greater formulation flexibility.

Due to the differences between liquid-filled hard capsule technology and softgel technology, many fill materials that are not suitable for softgels are well-suited for LFHCs. This includes:

- Insoluble hydrophobic materials – As compared to softgels, hard capsules can withstand a greater range of water content without compromising physical integrity.

- Moisture-sensitive materials – Hard capsules made from HPMC, which has a much lower water content than gelatin, are ideal for fills that have a high hygroscopicity.

- Oxidation-sensitive materials – Softgels are made with plasticizers, which create channels that make them more susceptible than hard capsules to the moisture and gas transmission that can oxidize the fill material.

- Materials with high melting points – While fills that melt at above 35° C are not candidates for softgels, LFHCs can be filled at up to 80° C.

- Formulations with large particles or fibrous materials – Although these can prevent a secure seal with softgels, they do not pose any problems for LFHCs.

- Smelly or foul-tasting materials – Because they have smaller channels than softgels, 2-piece hard capsules better mask unpleasant tastes and odors.

- Drugs that require abuse deterrence – Some companies in the pharma industry are now building abuse deterrence into their products, such as by using a high melting wax-based matrix formulation to reduce the drug’s extractability. Liquid-filled hard capsule technology enables mixing and filling at a temperature higher than the waxy component’s melting point.

Keep learning about gelatin and flavored capsules...

- Flavored capsules: the next customization level

- Tablets vs. Capsules: 5 Things to Consider

- Do you struggle with weight variation on your encapsulation machine?

LFHCs offer marketing advantages

The branding and marketing possibilities available with liquid-filled hard capsules can be important to OTC (over the counter) products in both the pharma industry and the nutritional supplements world. These possibilities include:

- Choice of capsule composition – The ability to use a vegetarian capsule is especially important for many nutritional supplement brands. Both gelatin and vegetarian (HPMC) two-piece hard capsules varieties are well-suited for liquid filling. Although vegetarian softgels are also available, they are only suitable for a few, simple liquid formulations.

- Purer product – Softgels contain 20 to 30% plasticizers. Hard capsules have significantly less, and sometimes no plasticizers or preservatives, which is important in markets where consumers demand “pure” products.

- Extensive branding options – Although softgels do offer some choices in terms of sizes and colors, brands have far more options with two-piece hard capsules. Nearly all aspects of the hard capsule can be customized: size, colors (including matching the brand’s PMS colors), printing, banding, material (gelatin or vegetarian), flavor and more. Plus, all of this branding—including printing—is done by the capsule manufacturer before the capsule is filled. This eliminates the fill material wastage that happens with softgels, which are printed after encapsulation.

Which is a better choice: softgels or liquid-filled hard capsules (LHFCs)? When you weigh the pros and cons for yourself, there are many reasons why the scales tip in favor of the capsules.