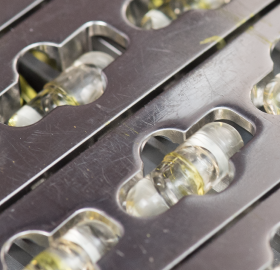

As the demand for nutritional supplements continues to grow, many brands are looking for ways to improve their products. For liquid- or oil-based supplements, Liquid-Filled Hard Capsules (LFHCs) offer so many benefits in terms of formulation flexibility, product efficacy, consumer appeal and bottom-line profitability that they warrant serious consideration as a preferred dosage form. Let’s take a look at each of these four areas.

Formulation Flexibility

When it comes to formulation flexibility, Liquid-Filled Hard Capsules really shine. LFHC technology enables things that are difficult or impossible to do using other encapsulation technologies, such as:

Directly encapsulate natural oils such as fish oil, garlic oil and coconut oil. This eliminates the need for synthetic excipients, which are undesirable when creating “natural” supplements. Hemp oil and cannabidiol (CBD) can also be encapsulated into LFHCs in their natural forms.

Mask unpleasant tastes of particularly strong-tasting ingredients, such as CBD oil and liquid fish oil. Two-piece hard capsules in general work well for masking undesirable flavors and provide an alternative to droplet formats.

Encapsulate materials with high melting points, such as coconut oil. Due to the details of their manufacturing process, softgels—another option for encapsulating liquids—cannot be used for materials with melting points above 35° C. In contrast, LFHCs can be filled at up to 80° C.

Combine otherwise incompatible ingredients, by using a combination filling format. For example, you can combine an oil with other active ingredients in the form of beads, micro tablets or pellets. All of these can be encapsulated together in the same two-piece hard capsule.

Combine otherwise incompatible ingredients, by using a combination filling format. For example, you can combine an oil with other active ingredients in the form of beads, micro tablets or pellets. All of these can be encapsulated together in the same two-piece hard capsule.

In addition, LFHCs require fewer excipients than tablets and powder-filled capsules, can be used with moisture-sensitive and oxidation-sensitive materials that will not work with softgels, and, unlike softgels, do not require the use of plasticizers or preservatives.

Product Efficacy

From the consumer standpoint, the most important benefit of LFHCs is that the use of suspensions or oil-based solutions increase the supplement’s bioavailability.

The ability to increase bioavailability is also important if your product contains active ingredients with poor water solubility. This is because LFHCs enables you to use a lipid-based formulation or make use of other liquid carriers. Using a lipid-based delivery system is one of the ways that formulators overcome absorption barriers and improve the bioavailability of poorly water-soluble compounds.

Suspending your ingredients in liquid also provides higher content uniformity for low-dose products, which also supports product efficacy.

Consumer Appeal

With their wide variety of color, band sealing and printing options, LFHCs can be extremely visually appealing. The endless combination of colors and imprints available with this dosage format also enables you to create highly-recognizable products with unique branding.

It is also important to note that LFHC technology works with both gelatin and HPMC vegetarian two-piece capsules. Many consumers in the nutritional supplements space specifically look for vegetarian or vegan products. Being able to encapsulate your liquid/oil supplements in vegetarian capsules instead of gelatin-based softgels can therefore be extremely important for consumer appeal.

Keep learning about capsule technology trends...

- Liquid-Filled Capsules: A New Way of Aspirin Delivery brings New Opportunities

- The Green Promise That Pharmaceutical Industry Should Make In 2022

- Halal and Kosher certifications: Their Importance For Your Product Development

Bottom-Line Profitability

LFHCs offer easier product development than softgels because there’s no need to formulate the shell itself and they’re easy to use with lab-scale equipment. Once you’re past the initial development stage, scale-up is linear. Then, when your product is in production, the LFHC process is much faster and less complex than softgel manufacturing and enables products to be made in more humid conditions.

All-in-all LFHCs offer a faster process for development, scale-up and launch. As they say, time is money, and being able to get to market faster can have a significant impact on your product’s profitability.

In addition, the LFHC process requires less containment when handling highly potent actives…another potential cost savings.

CapsCanada Offers LFHC Contract Manufacturing Services

As with any encapsulation choice, choosing the right manufacturer can also be critical to your product’s success. CapsCanada’s integrated services for Liquid-Filled Hard Capsules include everything from formulation assistance and product development through clinical trials, manufacturing in our dedicated LFHC facility, and commercialization.