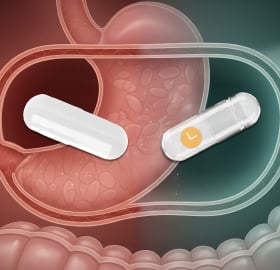

Many people take probiotics as an extra measure to help their bodies get the nutrients they need for a healthier life. Technically, the point of consuming a probiotic supplement is to introduce beneficial bacteria in the gut. Unfortunately, probiotics and stomach acid don't always mesh well.

The body’s naturally harsh stomach acid, needed to digest all kinds of food, kills off 99% of the probiotic strains from the major sources of probiotics long before these products can even get to the small intestine. So how do you get probiotics to cross the stomach and reach the intestine to grow and colonize, so the body can obtain the benefits they bring?

The vast majority of probiotics die from the extreme conditions they face when reaching the stomach. Therefore, the best way to get them through is by encapsulating them with an enteric coating or lining acting as a protective shield against gastric acids.

The Canadian Society of Intestinal Research suggests that in order to protect probiotics and encourage their absorption, it is recommended to cover them with an enteric coating acting as a barrier over them, thus preventing the capsule or pill from dissolving in the stomach acid.

Formulation and coating-process issues

It is one thing to encapsulate probiotics with an enteric coating so they can pass through the stomach, but another is to produce a formulation that protects them and, most importantly, that allows for easy and effective absorption by the body.

One of the best formulations for probiotic coating is hypromellose, a semi-synthetic polymer widely used in the Western Hemisphere for drug coating. Nevertheless, most enteric-coating processes all over the world are costly and complex, so it’s not just about the technology used, but also the entire coating process.

On the other hand, most probiotic coating formulations use added chemicals, solvents or other coatings to delay the release of the formulation as it passes through the digestive tract. Indeed, the capsule maintains its stability against stomach pH levels, but breaks down when it reaches the highest pH levels in the small intestine.

Keep learning about capsule technology trends...

- Gelatin capsules vs. HPMC capsules: What are the differences?

- Why Liquid-Filled Hard Capsules May Be a Better Option than Softgels

- Flavored capsules: the next customization level

Reducing the processing complexity in a first-level product

Regardless of the formulation of the drug or probiotic to be coated, as in this case, it is essential to look for one bearing low moisture content, in order to make it moisture or hygroscopic sensitive. Additionally, it must feature the following properties:

- Delayed release

- Gastric-acid resistant

- Low moisture content

- Cross-linking resistant

- Stability over a wide temperature and humidity range

- Wide regulatory acceptance for pharmaceutical applications

One of the best products on the global market using hypromellose technology and bearing all the previous features is CapsCanada’s AR-CAPS®. These gastric acid-resistant and cost-effective hard capsules prevent drug release into the stomach, making them a quality choice for a wide range of enteric pharmaceutical applications.

AR-CAPS® release the medicine by disintegrating in the duodenum for intestinal absorption, and are especially suitable for the delivery of probiotic and enzymatic formulations. And one of the company's best added values is that costly and complex enteric coating processes are completely eliminated.

As you have noticed, probiotics have a whole development behind them that allows them to be beneficial to health, without causing harmful effects on the digestive system. And although the market is full of these types of products, not all of them comply with the appropriate technology.

If you are looking for a probiotic formulation, bear in mind that quality must be the priority. In addition, look for an empty capsule supplier that carries a wide range of sizes that can be fully customized to align with your brand aesthetics and achieve maximum recognition and impact.