The CapsCanada's tamping simulator is a leading-edge tool specifically designed to improve capsule filling processes with tamping machines, such as Syntegon or Bosch. This simulator is the perfect solution for manufacturers who want to streamline production while maintaining quality. Here's a comprehensive look at how the CapsCanada Tamping Simulator can elevate your encapsulation process.

Why the Tamping Simulator?

Precision is essential in capsule filling, especially in the dosing area where powder is compressed into slugs before encapsulation. Trial and error type setup methods can be time-consuming and wasteful. However, with the Tamping Simulator, you can predetermine optimal machine settings before full-scale production. This process includes identifying the ideal dosing disc thickness, all five tamping station settings, and determining the correct powder level in the bowl. The result? Consistency across production batches and optimized performance.

To fully understand how works, we’ve created a step-by-step video series available on YouTube. Each video covers a different aspect of using this essential tool:

Part 1: Introduction

In this video, we provide an overview of the Tamping Simulator, highlighting its features and explaining its purpose in optimizing the capsule filling process.

Part 2: Set Up

This tutorial demonstrates how to properly set up the simulator, including capsule size selection, dosing disc thickness adjustments, and tamper pin configuration.

Part 3: Demo of Tamping Simulator with Powder

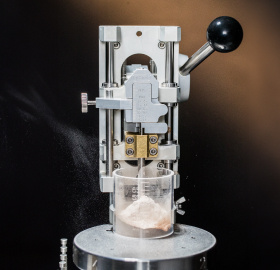

Watch a live demonstration of Simulator in action. We take you through powder loading, compression, ejection and slug evaluation to show how the simulator improves production accuracy.

Part 4: Achieving Target Weight Through Adjustments

Learn how to fine-tune the simulator’s settings to consistently achieve the target weight for each capsule size and formulation.

The Tamping Simulator is compatible with a variety of capsule sizes, ranging from 000 to 5, ensuring flexibility for manufacturers dealing with different product formulations.

Reducing Waste and Maximizing Quality

One of the standout advantages of the CapsCanada Tamping Simulator is its ability to minimize material waste. By simulating the powder compression process, you can quickly pinpoint the settings that produce the optimal slug weight. This reduces the need for excessive testing materials and ensures improved slug quality from the very beginning. By testing these settings in advance, you can also avoid common issues such as overcompression, which can damage filling machines and lead to costly delays.

For additional information guidance, refer to the CapsCanada’s Tamping Simulator Tool brochure.

Fine-Tuning Capsule Production

The Tamping Simulator makes the tamping process far more efficient. Operators can test each powder blend and quickly identify potential formulation challenges before full-scale production. For instance, if a powder is too sticky or difficult to compress, this can be detected early, saving both time and resources.

The simulator also includes a tamping spring scale that measures compression and ensures machines don’t exceed recommended limits. This feature helps prevent machine damage and ensures each capsule is filled consistently, contributing to superior quality control.

By testing all five tamping stations, manufacturers can fine-tune the production process to achieve the ideal slug formation and maintain tight control over capsule weight, reducing defects and production variability. CapsCanada’s simulator supports a wide range of formulations, ensuring adaptability to your specific production needs.

Real-World Applications and Results

The Tamping Simulator’s effectiveness has been validated in real-world settings. In one study, 25 different products were tested using the simulator, and the results were compared with those from Bosch machines. The findings showed minimal variation between the simulator and the actual machines when using the same settings, confirming its accuracy and reliability.

Without the simulator, operators often rely on trial and error, which can lead to inconsistent production, powder waste, and even machine downtime due to powder compatibility issues. The simulator helps manufacturers avoid these risks, ensuring a smoother and more streamlined production process.

Key Benefits of the CapsCanada Tamping Simulator

- Cost Savings: Reduce material waste and setup time by determining the best machine settings before production.

- Time Savings: Achieve target weight quickly, reducing unnecessary delays in the production line.

- Improved Slug Quality: Ensure consistent slugs formation with fewer defects, improving overall product quality.

- Increased Efficiency: Identify and adjust for formulation challenges in advance, reducing machine downtime and increasing production reliability.

Device Specifications

The Simulator is a comprehensive tool that comes with heavy-duty accessories, including a Pelican case for secure storage and protection. Installation and training by a CapsCanada® technician are included with the device.

Has a compact footprint of 11"W x 14"D x 24"H and weighs 50 lbs, making it ideal for benchtop or tabletop use. Please note that the table is not included with the device.

Conclusion

The Tamping Simulator is a game-changing tool for manufacturers using tamping-style capsule filling machines. By allowing you to simulate and optimize machine settings before starting full production, it reduces waste, boosts efficiency, and guarantees a higher-quality product.

Whether you're dealing with new product formulation or troubleshooting complex powders, the CapsCanada Tamping Simulator ensures your production process runs smoothly, resulting in fewer defects and better overall performance.

If you want more information, contact Steve Lee, CapsCanada’s Technical Manager, at slee@capscanada.com.