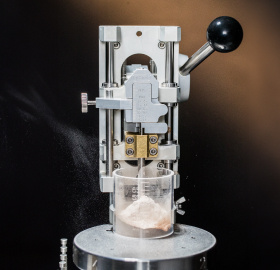

As the rectified capsule descends with optimal alignment into the upper segment bore, the separation phase begins. Vacuum flows through individual holes in a vacuum shoe seated against the lower side of the body tooling, pulling the body down, just as the cap is seated in the upper segment.

Proper cap and body separation are achieved when each of the respective capsule halves are fully seated within the upper and lower tool. Using too much vacuum may create pin-hole defects in the body dome or cause the caps to pop off before they can fully seat. Too little vacuum will lead to non-separation, creating waste and dirty tooling. Another common result is a body fold defect, where the body does not seat and is then crushed during the filling step.

To assure the right level of vacuum for each lot of capsules, reduce vacuum until you see non-separation, and then ease the vacuum level up until consistent separation is achieved.

In the next technical tip, we will address proper adjustment of separation pins for applicable machines.